plating thickness tester how it works|anodizing thickness measuring instrument : wholesaler This is about How to use coating thickness tester and how to measure plating thicknessSubscribe YouTube Channel - https://www.youtube.com/c/AskMechnology/Fac. Surviving Paradise 2023 | Maturity Rating: 16+ | 1 Season | Reality TV In this reality competition, players must form alliances and fight to move from the wilderness into a .

{plog:ftitle_list}

Loppuvuodesta 2020 päivänvalon nähnyt Wild Fortune on oikein mainio nettikasino. Mutta tarjoileeko tämä nettikasino niin villiä menoa, kuin sen nimi . Ver mais

bottled water testing results 2015

Paint and coating thickness is determined by measuring this pull-off force. Thinner coatings will have stronger magnetic attraction while thicker films will have comparatively less magnetic attraction. Testing with magnetic . This is about How to use coating thickness tester and how to measure plating thicknessSubscribe YouTube Channel - https://www.youtube.com/c/AskMechnology/Fac.

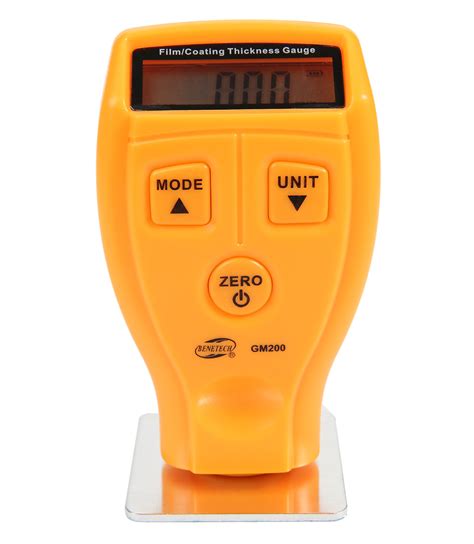

Paint thickness gauges are essential tools for measuring the thickness of coatings on various surfaces.They are widely used in automotive refinishing,industrial coating applications,and many other fields where the quality and durability of coatings are critical.In this article,we will provide a comprehensive guide to paint thickness gauges,explaining how they .Coating thickness measurement/Dry film thickness measurement is used to determine the thickness of coatings on components and to monitor the coating process. Our measuring instruments solve a wide range of applications in . Usually, a plating thickness gauge is used to control the plating thickness. (2) Anode plating. The plating metal of the anodic plating is more active than the substrate. When the plating layer encounters corrosive .L373 – Advanced, Portable Coating Thickness Gauge – Portable Elegant in their simple design, the 373 is the latest two-piece coating thickness tester from Kett. Offering our unsurpassed three-year warranty, the 373 provides unsurpassed capabilities in a .

bottled water testing safety

Given the potential combinations of 3D printable materials, a variety of plating metals, and plate thickness ratios, it’s easy to see how electroplating gives engineers a new field of design options to consider. inar . and turn them into more durable works of art. In the medical community, electroplating is used to make medical implants .Congratulations on your purchase of the Extech CG204 Coating Thickness Tester. The CG204 is a portable meter designed for non-invasive coating thickness measurements. The meter uses two measurement methods: magnetic induction (for ferrous metal . If the probe is placed on a non-ferrous metal it will work in the eddy current mode. In the . The thickness gauge measures eddy current strength and the respective magnetic field produced and then calculates the thickness of the nonconductive coating. This test is often employed to measure the thickness of anodized aluminum and can also be used to measure phosphate coatings and paint thicknesses.Electroplating is a popular metal finishing and improving process used in a wide range of industries for various applications. Despite the popularity of electroplating, however, very few outside of the industry are familiar with the process, what it is and how it works. If you’re considering using electroplating in your next manufacturing process, you need .

Plating, the process of covering a substrate with a thin layer of metal, plays an essential role in modern manufacturing and materials science. The thickness of the plating layer is a critical parameter that can significantly impact the finished product’s performance, durability, and aesthetic qualities. In industries where precision is non-negotiable, such as aerospace, .All combs work in the same way. How do you use a wet film paint thickness gauge? . The spray shop supervisor or inspector generally has the job of DFT testing. They often measure coating thickness at various stages of the project to check that each coat is up to standard and suitable to over-paint. A final check at the end of the project .

A reversible anvil lets you adapt the gauge to the shape of the object you are measuring. Use the round face on the anvil to measure the wall thickness of pipe, tubing, and other curved surfaces. Use the flat face to measure sheet metal, paper, and other flat stock.Elcometer offer a range of digital coating thickness gauges from the new Elcometer 456 - available with either integral or separate probes, the Elcometer 415 Paint and Powder Thickness Gauge, to the Elcometer 311 Automotive Refinishing Gauge.Single Coat Applications: A minimum coating thickness of 13µm (0.5 mil) on a flat metal substrate with a minimum thickness of 1.25mm (50 mils) is usually required. Multi-Layer Applications – Total thickness: In many circumstances, the total thickness of a multi-layer coating system over metal can be reliably measured. As in single coat .Q: What should a coating thickness gauge read on a G90 galvanized coating? A: According to ASTM A653, a G90 coating designation means the weight of zinc on both sides of a steel sheet is 0.90 oz./ft2. A magnetic thickness gauge measures only one side. Therefore: 0.45 oz./ft2 x 1.684 = 0.76 mils per side; 0.45 oz./ft2 x 42.78 = 19 microns per side

We work hard to protect your security and privacy. Our payment security system encrypts your information during transmission. . Coating Thickness Tester, Electronic, Base Material Ferrous And Nonferrous Metals, . An additional bath in an undercoating medium adheres to the base material, which improves the bond with the plated coating. Thickness of the coating depends on how long the parts are held in the bath (i.e. dwell time) as well as the complexity of the part geometry and features. These can also affect how even or uniform the coating is.

The Infinita Lab 211, commonly known as the “banana gauge,” is a more precise coating thickness gauge that works well on cold and submerged surfaces. The Infinita Lab 101, on the other hand, will give you quick and instant results. Measurement Tools for Coating Thickness.

All New Elcometer 456 Top Ferrous metal substrate coating thickness gauge with integral probe. Range: 0-60 mils. Memory stores up to 150,000 readings in up to 2500 batch files that are each capable of storing a distinct calibration. Three . The test works on the principle of magnetic induction. The instrument generates a magnetic field, and the response from the substrate (through the non-magnetic coating) is measured. The thickness of the coating affects this magnetic response, allowing the instrument to calculate the coating thickness.The CC-100 Thickness Tester uses a chromatic confocal measuring principle to determine the thickness of transparent layers. . Identify critical component locations with low conformal coating thickness No Ground Plane Required. Measurements work directly on coated boards.An eddy current thickness gauge measures the thickness of non-conductive coatings on non-magnetic substrates such as copper, aluminum, and brass. ECT gauges detect common coating defects, including corrosion, cracking, erosion, thickness loss, and material degradation.

The in-line plating method uses an assembly line for the metal plating operation. The metal passes through the various stations and automated machinery facilitates the chemical reaction. Line plating is generally used for coating copper, zinc, chromium and cadmium. A variety of substrates can be coated with these metals through line plating.Destructive testing of thickness is also valuable for coating failure investigations. . The total coating thickness is approximately 10 to 15 mils. Step 2: Select a Cutting Tip . might work. Likewise, if the coating or substrate are rough, causing the angle of the groove cutting instruments to vary, the grinding or drill bit procedures . to learn more about DFT meter please click: www.iogs.orgThe video is showing DFT meter information but also try to cover the following subject:-Coating thic.

The importance of measuring coating thickness is discussed extensively in the “How to Measure Coating Thickness” article. When it comes to selecting a handheld portable coating thickness gauge, an incorrect instrument choice may result in a measurement failure (e.g., inability to obtain a value) or completely wrong results. Even when a false reading is .You can find coating thickness gauges suitable for measuring either wet film thickness, dry film thickness or both – and we’ve gathered everything you need to know about how a gauge works and how to go about taking a reading. How a coating thickness gauge works. A coating thickness gauge is designed to measure how thick a coating is.

It consists of LS225+F500 multi-probe coating thickness gauge host and F500 probe. LS225+F500 plating thickness gauge is specially used to detect copper, zinc, tin, chromium and non-magnetic coatings on iron and other ferromagnetic metal substrates. The plating thickness gauge has ultra-high measurement accuracy and repeatability.

precise coating thickness gauge

plating thickness tester price

plating thickness measuring instrument

WEBPena Ajena - watch online: streaming, buy or rent . Currently you are able to watch "Pena Ajena" streaming on VIX for free with ads.

plating thickness tester how it works|anodizing thickness measuring instrument